Tracks provide guidance in a broad range of technical applications, from classic railway tracks and crane rails to positioning systems. All of them, however, have one thing in common: Direction, height, and distance have to fit together within very small tolerances.

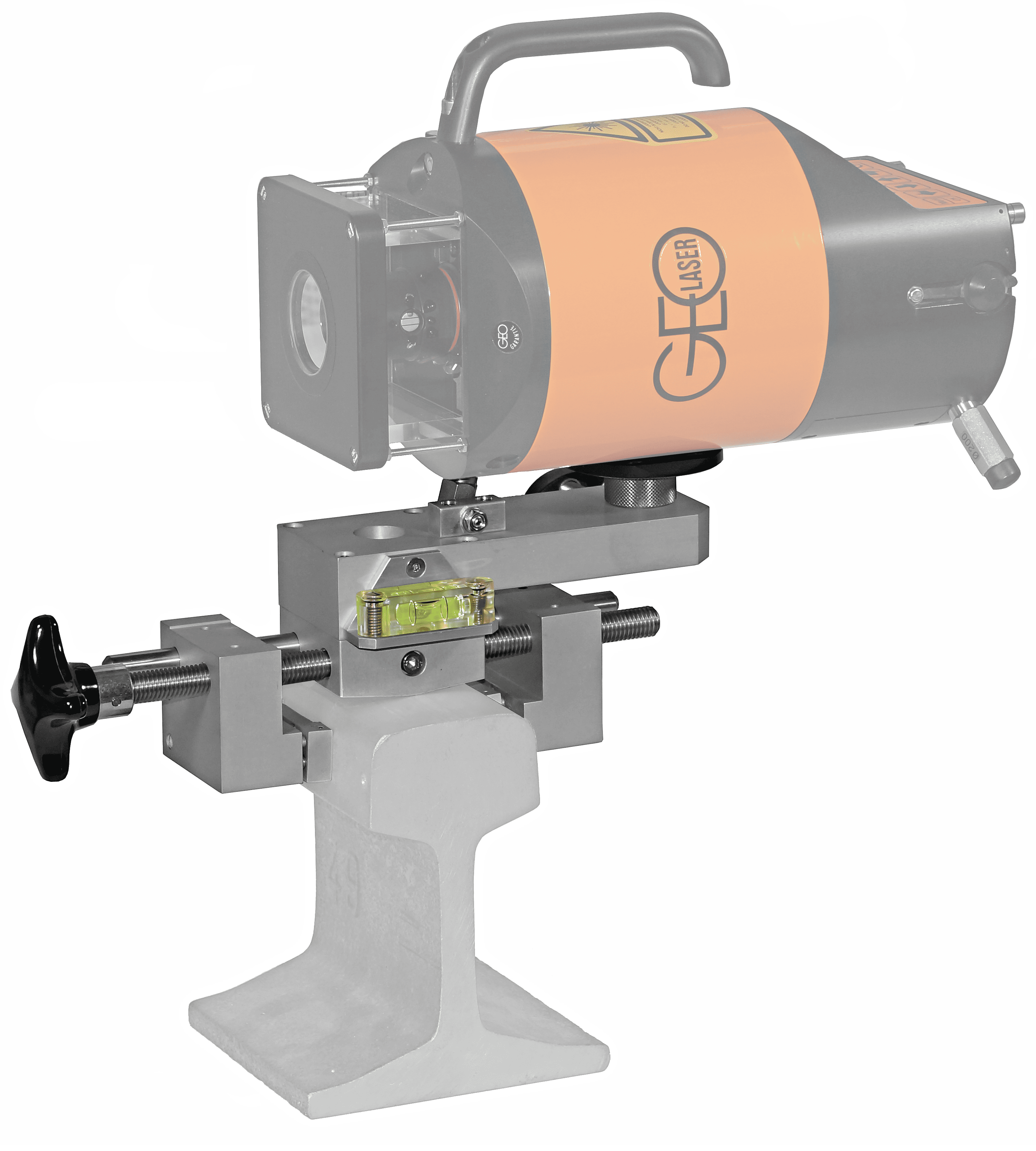

To determine the height, a self-levelling rotary laser is of great service. It projects a rotating laser plane into space to serve as a plane of reference. The rail head is then scanned, using a mechanical scanning device and, permanently attached to it, a precision laser receiver. In our reference class, we offer precision laser receivers with a resolution of up to 1/100 mm.

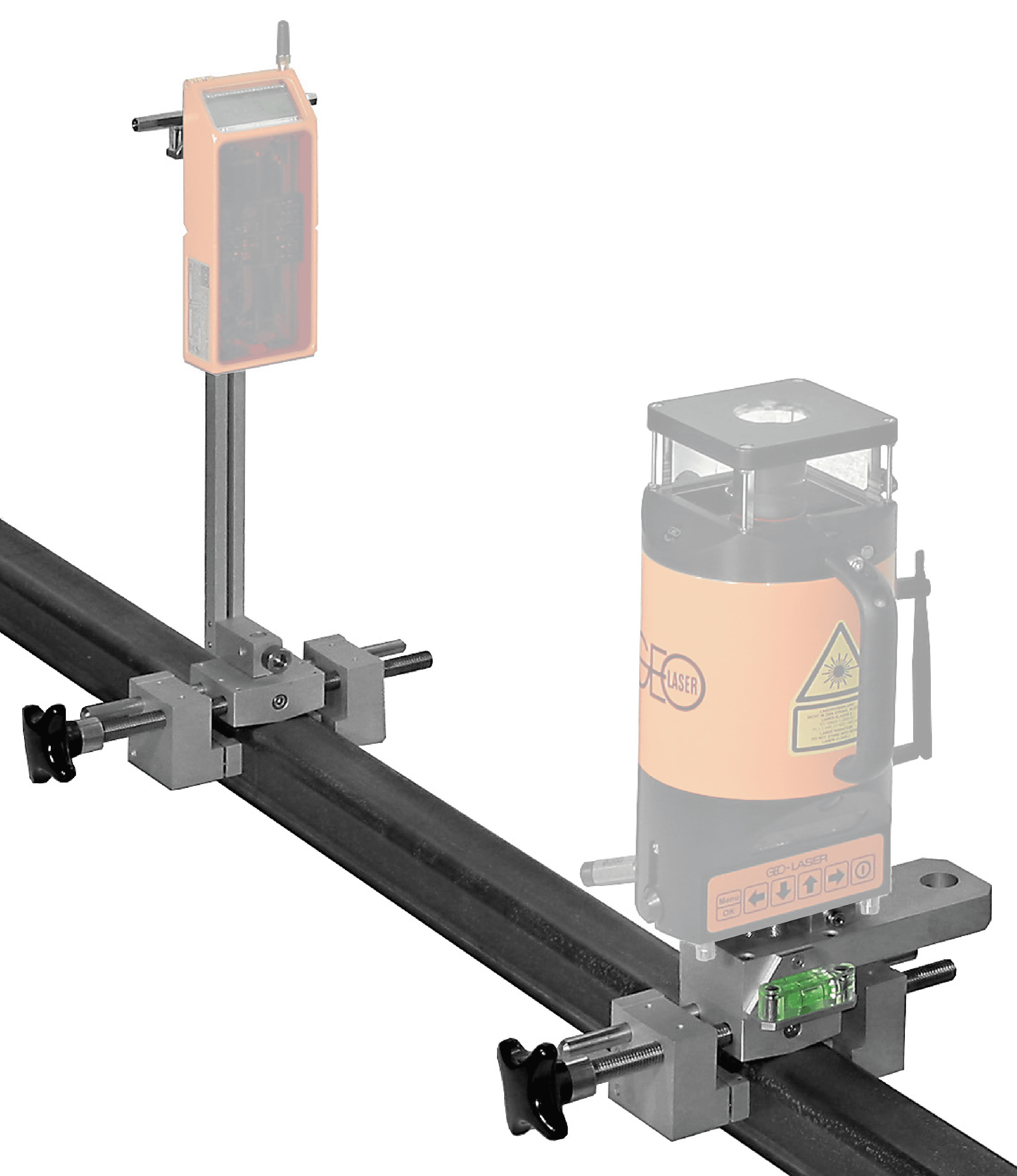

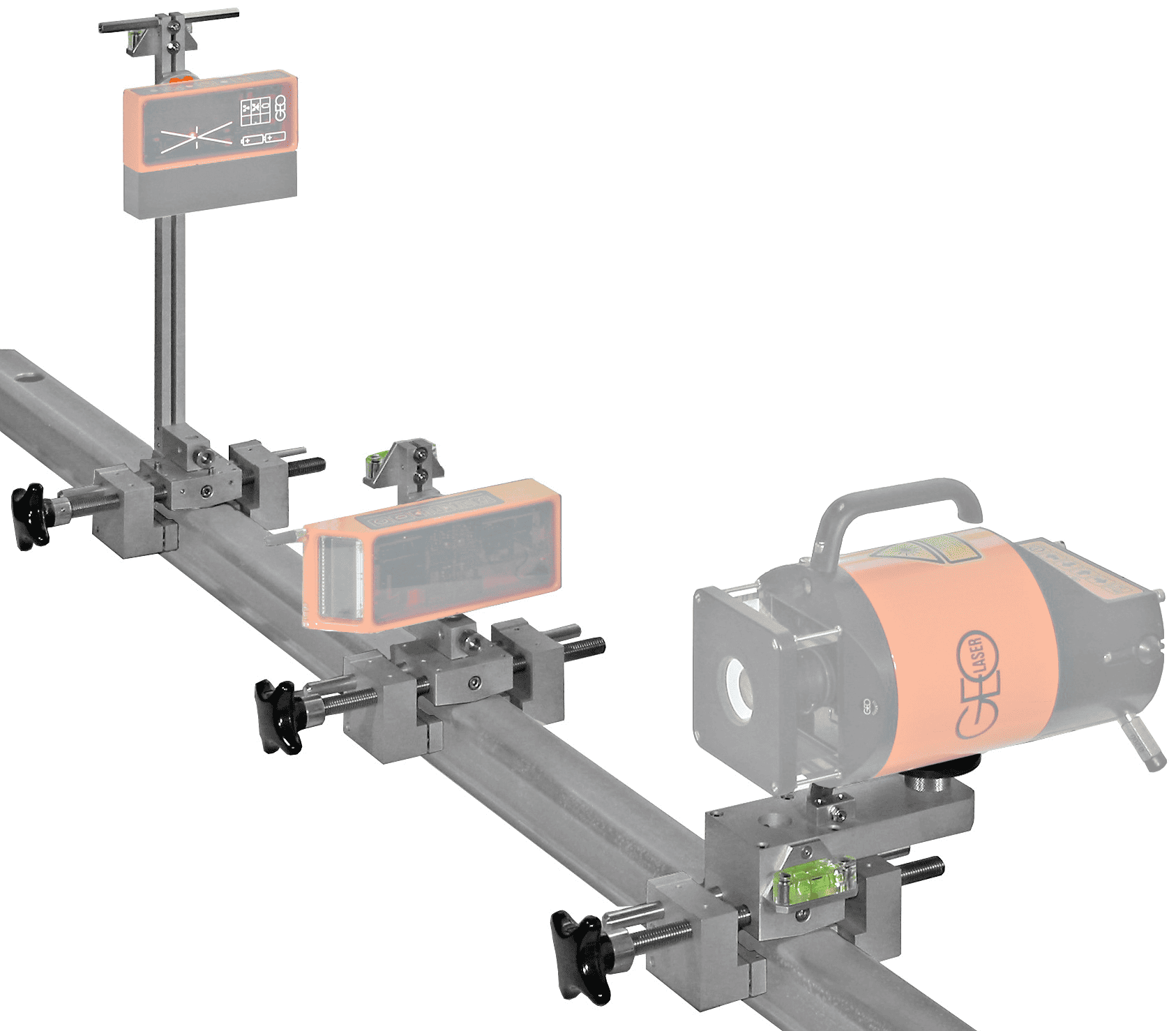

To check straight alignment and linearity of the track, a horizontally operated laser is set up above the starting point in such a way that the rotating laser plane exits via the rail head’s center. A locking receiver is mounted above the end point in the same way. The receiver then guides the laser via radio control onto its central position. This way, a vertical laser plane is created that passes through both end points with maximum precision. With a special mechanical adapter as well as a precision laser receiver, the track can now be scanned and its lateral deviation from the target axis be determined.

For these special measuring tasks, GEO offers a variety of clamps and adapters that are self-centering via the rail head, enabling easy setup of both laser and laser receiver.

You can find an example of application in the download area of the internet presence of the company DEMAG.

Control principle of the Locking Receiver

Setup for measuring the height

Setup for measuring the alignment